Welding Consultation and Coordination Services

We collaborate closely with our clients throughout all project stages, providing technical and problem-solving consultations to ensure the quality and safety of welding processes and products. Our focus is on compliance with industry standards and codes while also ensuring robustness and security.

Welding Consultation

It helps maintain quality, reliability, customer satisfaction, and compliance with international standards, ultimately leading to a safer and more effective product.

Welding coordination

Welding coordination is a critical function in various industries, and it involves managing and overseeing all aspects of welding activities to ensure quality, safety, and compliance with industry standards and codes.

Here is a breakdown of the key responsibilities and tasks involved in welding coordination:

1. Planning

Develop a comprehensive plan for welding activities, including project-specific requirements, resource allocation, and scheduling.

2. Performing

Depending on the role and qualifications, a welding coordinator may actively engage in welding activities, ensuring that the work is done correctly and efficiently.

3. Supervising and/or Overseeing

Monitor and manage welding operations, including personnel, equipment, and materials, to ensure compliance with established standards and quality requirements.

4. Reviewing Conformity

Review welding activities to ensure they adhere to relevant industry standards and code requirements.

5. Technical Review

Provide technical expertise and support, including reviewing and approving welding procedure specifications (WPS) and welding procedure qualification records (WPQR).

6. Control and Surveillance of Subcontractors

Oversee and assess the qualifications and suitability of subcontractors and welding personnel involved in the project.

7. Preparing WPS and WPQR

Develop and maintain welding procedure specifications and qualification records, which outline the specific welding processes and parameters to be used.

8. Control and Surveillance of Work Instructions

Ensure that work instructions are followed correctly and consistently, providing guidance for welding activities.

9. Material and Welding Consumable Selection

Select appropriate materials and welding consumables that are compatible with project specifications and requirements. Control the documentation, storage, and handling of these materials.

10. Inspection and Testing

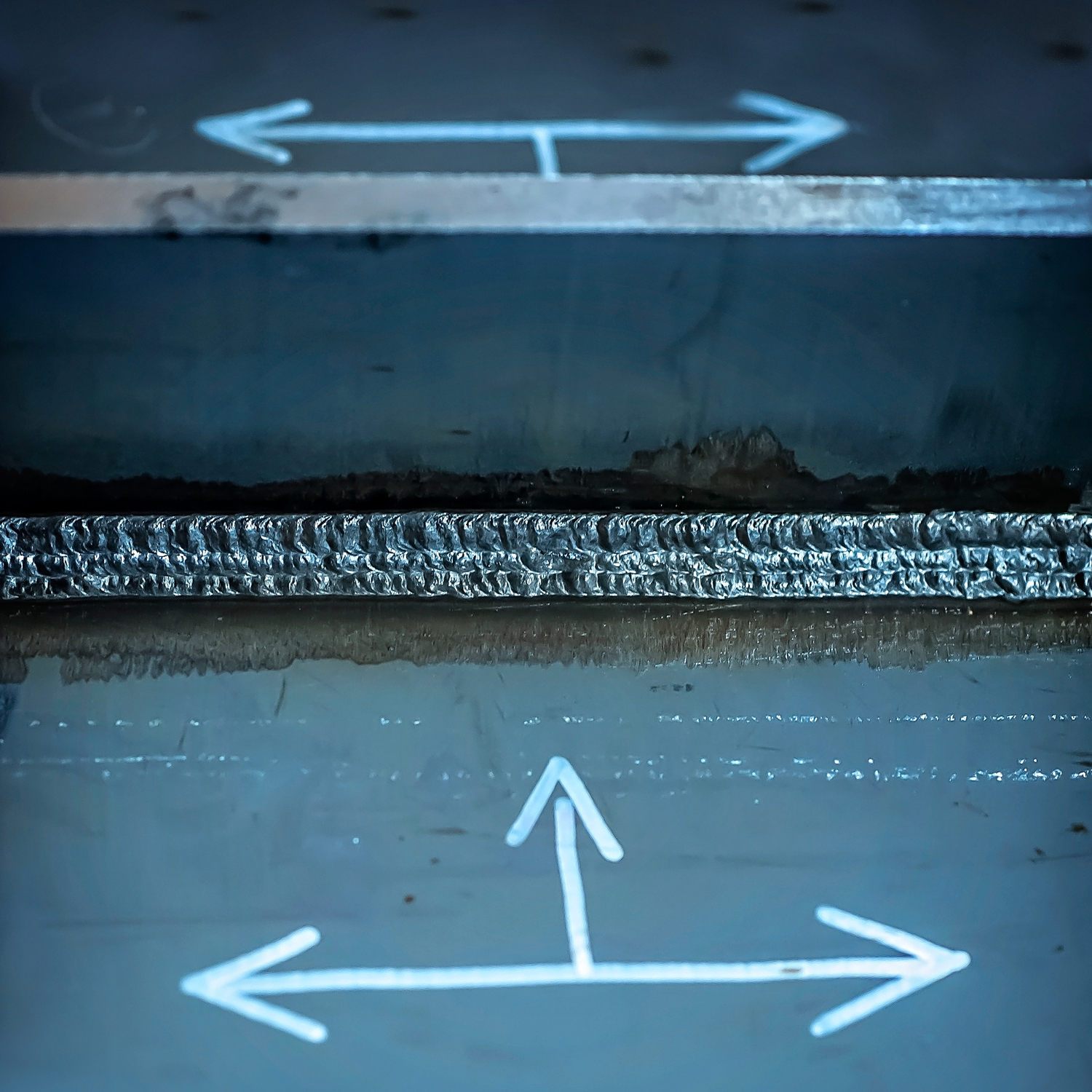

Oversee the inspection and testing processes, which may include visual inspections, non-destructive testing, and destructive testing, before, during, and after welding.

11. Corrective Actions

Implement corrective actions in response to non-conformances, such as weld repairs and reassessment of repaired welds.

12. Equipment Control

Ensure that welding equipment is suitable, well-maintained, calibrated, and validated to meet project requirements.

13. Identification and Traceability

Maintain proper identification and traceability of welded components and materials, which is crucial for quality control and documentation purposes.

14. Quality Record Preparation

Create and maintain records of welding activities, inspections, and test results to document compliance and ensure traceability.

15. Additional Requirements

Prepared to accommodate any other coordination requirements specified by the manufacturer, contract, or application standard witch may vary depending on the specific project or industry.

Welding Inspection

Our competent Welding Inspector IWI-C perform, supervise or oversee agreed welding and welding-related inspection activities during various stages of fabrication such as before welding, during welding and after completion of the welds.

International Welding Inspector Comprehensive (IWI C) services include:

- Perform, supervise or oversee agreed welding and welding-related inspection activities;

- Review and application of welding instructions, welding procedure specifications and qualified welding procedures;

- Preparation and implementation of inspection procedure and acceptance criteria;

- Quality Control;

- Audits;

- Control of welding equipment functionality and application;

- Inspection according requirements based on national specifications and codes.

Any other requirements can be specified by a manufacture, a contract or an application standard.